Hook up Led to Pi Pwm Dam Hyperion, Applications, Technology & More

Introduction to Hook up Led to Pi Pwm Dam Hyperion

In the realm of electronics and engineering, the potential for innovation often lies in the interplay of simple components. The “Hook Up LED to Pie PWM DAM” system exemplifies this concept, showcasing how a blend of fundamental and advanced technologies can yield impressive results. This intriguing setup not only serves as a functional circuit but also embodies a strategic framework for enhancing efficiency and fostering creativity in design.

This system uses Pulse Width Modulation (PWM) to precisely adjust an LED’s brightness, showcasing the ability to combine simple components to get complex results. This integration opens up new circuit design opportunities for both professionals and enthusiasts, leading to improvements in a range of applications. All things considered, this configuration signifies a change in contemporary electronics toward creative problem-solving and effective design rather than merely joining components.

Understanding the “Hook Up” in Electronics

In the sphere of electronics, the time period “hook up” refers back to the crucial method of connecting numerous components to create a practical circuit or device. This elaborate system ensures that gadgets which include LEDs, controllers, and drivers are well linked to electricity resources and each other, abiding by using the essential concepts of electrical engineering. Properly executing this step is critical, because it lays the foundation for the device’s capability and efficiency.

The Power of LEDs: Illuminating Modern Applications

Light Emitting Diodes (LEDs) have revolutionized the manner we think about lights. Unlike conventional incandescent bulbs, LEDs are semiconductor gadgets that emit mild whilst an electric powered cutting-edge passes through them. This modern generation offers several blessings, making LEDs a really perfect choice for a big range of packages.

One of the most extensive benefits of LEDs is their strength efficiency. They devour a long way less strength than conventional lighting alternatives, reducing electricity bills and environmental effects. Furthermore, LEDs boast an outstanding lifespan, regularly lasting tens of lots of hours, which translates to much less frequent replacements and decreased protection charges. Their ability to provide mild in a lot of colors and intensities additionally allows for specific control, permitting designers to create dynamic lights answers for the whole lot from simple indicators to complex displays.

Piezoelectric Technology: Harnessing Mechanical Pressure

The time period “Pie” in the context of this dialogue usually refers to piezoelectric components, which can be materials that generate an electrical rate while subjected to mechanical stress. This unique property makes piezoelectric sensors priceless in various applications, ranging from automotive systems to patron electronics.

When mechanical stress is carried out to a piezoelectric fabric, it creates an electric signal proportional to the amount of pressure skilled. This capability is important for gadgets that require specific measurement of bodily forces, which include pressure sensors and accelerometers. By changing mechanical energy into electric indicators, piezoelectric components can enhance the interactivity and responsiveness of digital structures.

Pulse Width Modulation: Fine-Tuning Power Delivery

Pulse Width Modulation (PWM) is a technique used to modify the quantity of power brought to an electronic device via breaking the electricity into discrete on-off pulses. This technique permits efficient control over devices such as LEDs, taking into consideration adjustments in brightness without wasting electricity.

PWM works by way of varying the period of the “on” state relative to the “off” nation in a pulse cycle. This ratio, known as the duty cycle, determines how plenty strength is added to the tool. By manipulating the obligation cycle, engineers can acquire the desired brightness for LEDs, making PWM an crucial tool in energy-efficient lights designs.

The Role of a “Dam” in Electronic Circuits

In electronic terms, the metaphor of a “dam” can represent a component or system that regulates the flow of electrical signals within a circuit. This control is vital for maintaining the functionality and stability of the system. Just as a dam manages the flow of water to prevent flooding or optimize resources, an electronic dam ensures that signals are delivered appropriately to prevent overloads or inefficiencies.

In the “Hook Up LED to Pie PWM DAM” setup, the dam component plays a critical role in regulating electrical signals based on input from piezoelectric sensors. By controlling the flow of power and signals, this system ensures that LEDs operate optimally under varying conditions.

Advantages of Integrating LED, Piezoelectric Components, and PWM

Combining LEDs, piezoelectric elements, and PWM manage offers a multitude of blessings for modern-day electronic applications:

1. Energy Efficiency

LEDs are already strength-efficient, and the mixing of PWM enhances this performance even further. By exactly controlling the strength delivered to the LEDs, the system minimizes wasted electricity, contributing to sustainability and decrease operational expenses.

2. Enhanced Control

The use of piezoelectric sensors introduces a stage of responsiveness this is useful in dynamic environments. This technology allows structures to conform in real-time to user interactions or environmental adjustments, ensuing in greater intuitive and attractive user reviews.

3. Innovative Applications

The aggregate of those technologies paves the manner for brand new opportunities in layout and capability. For example, contact-responsive lights structures can create immersive stories in museums or exhibitions, at the same time as smart home technology can adapt to users’ possibilities primarily based on their interactions.

Drawing Parallels: The Dam Analogy

The analogy of a dam controlling water flow serves as an excellent metaphor for understanding how the “Hook Up LED to Pie PWM DAM” system operates. Just as a dam regulates the water to prevent overflow and optimize resource management, the electronic dam in this setup governs the flow of electrical signals.

1. Regulation of Flow

Much like a dam controls water release through sluice gates, the PWM and dam components in the circuit manage the electricity supplied to the LED. By adjusting the duration and frequency of electrical pulses, PWM effectively changes the LED’s brightness, ensuring optimal performance without wastage.

2. Response to Pressure

In the analogy, the piezoelectric sensor acts as a water level monitor, detecting changes in pressure that inform how the dam should react. Similarly, in our electronic system, the sensor measures environmental inputs, adjusting the LED’s intensity based on external conditions. This dynamic interaction enhances the overall user experience by providing feedback that feels immediate and responsive.

3. Energy Efficiency

Dams are engineered to maximize the efficient use of water, and the integration of PWM with piezoelectric inputs serves a similar purpose in electronic systems. This technology ensures that the energy supplied to the LEDs aligns with current demands, minimizing waste and extending the lifespan of components.

4. Safety and Stability

Dams are equipped with features to manage extreme conditions, such as floodgates and spillways. In an electronic circuit, safety mechanisms can prevent overloads or excessive input from piezoelectric sensors, ensuring that the system remains stable and operational even under varying conditions.

Practical Applications of the LED-Piezo-PWM-DAM Setup

This innovative electronic configuration has numerous practical applications across various fields:

1. Interactive Installations

In environments like museums or exhibitions, touch-sensitive lighting can significantly enhance visitor engagement. By incorporating piezoelectric sensors and PWM-controlled LEDs, installations can respond dynamically to audience interactions, creating memorable experiences.

2. Smart Lighting Systems

In residential and commercial settings, integrating touch-responsive elements with ambient lighting can lead to adaptive environments that respond to human presence and preferences. This approach not only improves energy efficiency but also enhances comfort and convenience.

3. Wearable Technology

In fitness and health monitoring devices, user interactions can trigger visual feedback through LEDs, providing immediate information about performance metrics. By employing piezoelectric sensors, wearables can offer responsive interfaces that motivate and inform users.

Addressing Common Challenges

While the integration of these technologies is promising, several challenges may arise:

1. Complexity in Calibration

Calibrating piezoelectric sensors to accurately translate mechanical pressure into the corresponding electrical signals can be intricate. Employing calibration software during setup can streamline this process, ensuring precise performance.

2. Interference and Noise

Electrical noise can disrupt the PWM signals, impacting system performance. Implementing shielding techniques and noise filters can enhance signal integrity, providing reliable operation in various environments.

3. Power Supply Issues

An inconsistent power supply can adversely affect PWM performance and, consequently, the LED’s brightness. Using regulated power supplies can mitigate this issue, ensuring that the system operates smoothly and effectively.

Understanding Pulse Width Modulation (PWM) and Its Applications

Pulse Width Modulation (PWM) is a effective digital approach hired to manipulate energy transport to electrical gadgets correctly. By rapidly switching the energy on and stale, PWM lets in for unique control over the amount of strength supplied to a device. This method is widely utilized in numerous packages, from controlling motor speeds to adjusting the brightness of LEDs.

The Basics of Pulse Width Modulation

At the core of PWM lies the concept of the obligation cycle, which refers to the share of time that the sign is “on” (excessive) in comparison to while it’s far “off” (low). The responsibility cycle is expressed as a percent:

- A hundred% Duty Cycle: The electricity is continuously on, turning in full voltage to the tool.

- 50% Duty Cycle: The energy is on for half the time and rancid for the alternative half of, efficaciously offering 1/2 the average energy.

- Zero% Duty Cycle: The power stays off at all times.

This flexibility in energy management permits PWM to function efficaciously with out generating immoderate warmness, making it specially appropriate for applications like motor control and LED dimming, where retaining particular ranges of brightness or velocity is vital without incurring high expenses or complexity.

The Benefits of Using PWM for LED Control

LEDs (Light Emitting Diodes) are contemporary-driven devices that require cautious law to acquire preferred brightness ranges. Without PWM, an LED might either be completely illuminated or absolutely off, imparting no intermediate states for brightness manage.

By implementing PWM, you could effectively modify the brightness of an LED through converting the length for which electricity is implemented. This approach isn’t always handiest strength-green however additionally straightforward to set up, especially when using a microcontroller.

Components Required for LED Control with PWM

Before you could connect an LED to a PWM-enabled pin, you’ll need to gather the following additives:

- LED: The primary factor that emits light while powered.

- Resistor: Essential for limiting the cutting-edge flowing via the LED to prevent harm. A resistor with a cost of 220 ohms or 330 ohms is commonly appropriate for maximum fashionable LEDs.

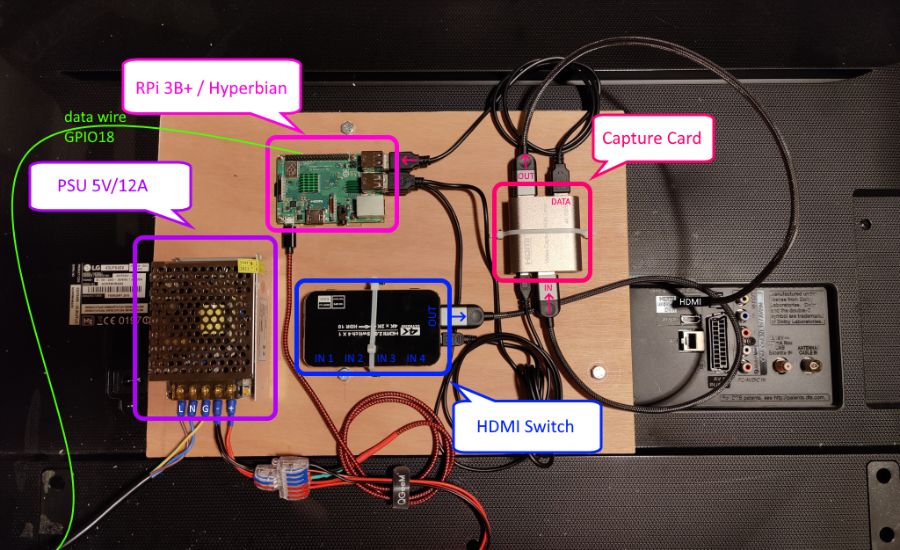

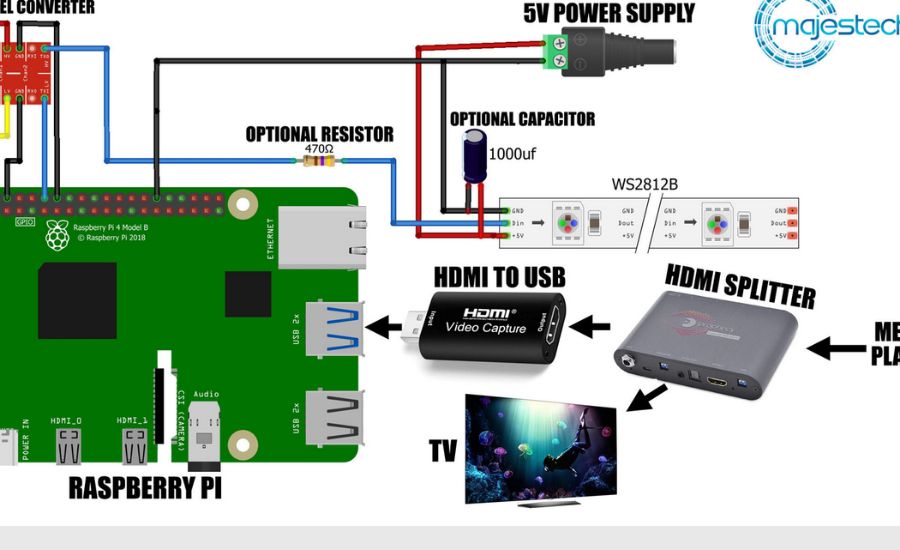

- Microcontroller (e.G., Arduino or Raspberry Pi): This device generates the PWM signal, with committed PWM pins available for output.

- Wires: Necessary for making connections among the additives, whether on a breadboard or without delay.

- Breadboard (optional): Useful for prototyping and checking out your circuit without soldering.

- Power Source: This might be a USB electricity deliver or an outside supply for powering the microcontroller.

Wiring the Circuit: A Step-by-Step Guide

Setting up an LED with PWM involves several straightforward steps:

Step 1: Choose a PWM Pin

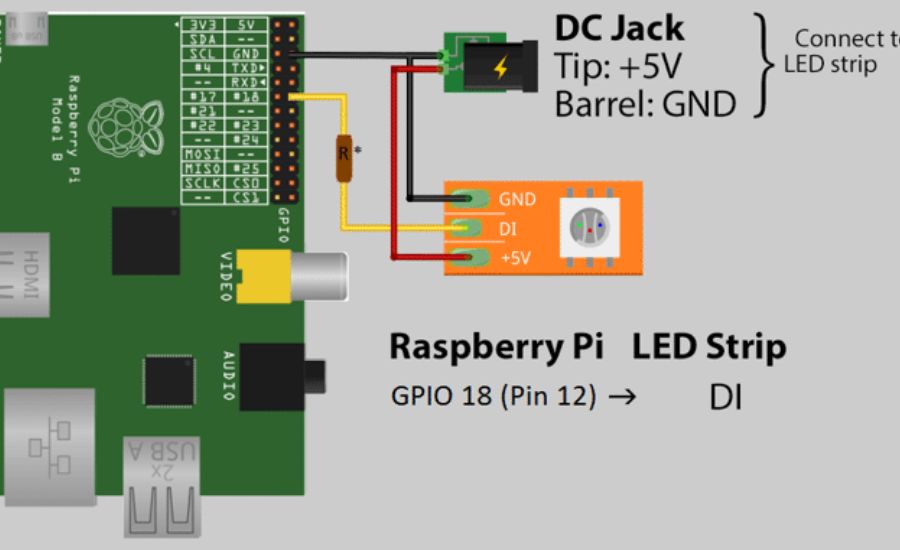

PWM output is enabled on particular pins of microcontrollers inclusive of the Arduino and Raspberry Pi. Look for pins on Arduino forums that have the sign “~” on them; they may be typically pins three, 5, 6, 9, 10, and 11. With the right software program libraries, the Raspberry Pi can use any GPIO pin for PWM.

Step 2: Connect the LED and Resistor

- Anode (Positive Lead): Connect the anode of the LED to one end of your resistor.

- Cathode (Negative Lead): The cathode should connect directly to the ground (GND) pin of your microcontroller.

Step 3: Link the Resistor to the PWM Pin

Connect the free end of the resistor to your chosen PWM-enabled pin on the microcontroller (for instance, pin 9 on an Arduino).

Step 4: Power Up the Microcontroller

With the wiring complete, you can power up your microcontroller and prepare to program it for PWM control.

Advanced Techniques for Utilizing Pulse Width Modulation (PWM) with LEDs

Pulse Width Modulation (PWM) has revolutionized the way we manage light output in LED era. This approach allows for dynamic manipulate over brightness and shade, making it an essential technique in cutting-edge electronics. Below, we explore superior PWM techniques tailored for LEDs and their practical applications across diverse domain names.

Achieving Smooth Color Transitions with RGB LEDs

RGB (Red, Green, Blue) LEDs are particular additives that allow for a wide spectrum of colors while blended in various intensities. By using PWM, you can independently control the brightness of every color channel.

For example, adjusting the obligation cycle for the red, green, and blue channels one after the other allows you to create an extensive array of color combinations. When the responsibility cycles for those channels are modulated, the ensuing blending of mild can produce the entirety from diffused pastels to vibrant colorings, best for artistic lighting fixtures setups or interactive shows. This approach is specifically precious in applications in which atmosphere and mood lights are important, consisting of in theaters or concert venues.

Dimming Multiple LEDs Simultaneously

One of the remarkable capabilities of microcontrollers is their ability to manage multiple PWM signals across different pins. This feature allows you to control the brightness of several LEDs either independently or in unison.

For example, you might design a system where certain LEDs brighten or dim based on user interaction or environmental conditions. In settings such as smart homes, this functionality can contribute to energy savings and personalized lighting experiences. Moreover, you can create synchronized lighting effects that enhance the atmosphere of events or installations, where a cohesive lighting theme is essential.

Control Over LED Matrix Displays

PWM is particularly effective in LED matrix displays, where each individual pixel can be controlled independently. In large-scale displays, such as those used in advertisements or public information boards, the ability to adjust the brightness of each LED enhances image quality and overall visibility.

Using PWM, you can produce detailed animations and graphics with varying brightness levels, making your visuals more engaging and appealing. This technique allows for more complex visual storytelling, as subtle shifts in light can convey emotions or information effectively.

Practical Applications of PWM in Lighting

Energy Efficiency

One of the standout advantages of using PWM for LED control is energy efficiency. Traditional resistive dimming methods waste power as heat, which can be a significant drawback in battery-operated devices. In contrast, PWM efficiently modulates power without generating unnecessary heat. This makes it an ideal choice for sustainable lighting solutions, allowing for longer battery life and reduced energy costs.

Fading Effects for Enhanced Visual Appeal

PWM-controlled LEDs are widely employed in creating fading light effects for mood lighting and visual displays. The smooth dimming and brightening capabilities can enhance the aesthetic appeal of various products, from home décor to automotive lighting systems. Such effects can evoke specific emotions or themes, making them popular in design-oriented applications.

Motor Control in Robotics and Automation

Beyond lighting, PWM is also instrumental in controlling DC cars in robotics and industrial applications. By modulating the power supplied to a motor, you may finely music its speed and torque, bearing in mind specific motion and operation. This versatility has made PWM a useful tool in automation and robotics, wherein accuracy and efficiency are paramount.

Troubleshooting Common PWM and LED Issues

Despite its many advantages, working with PWM and LEDs can present challenges. Here are some common issues and solutions:

Flickering LEDs

A low PWM frequency might be the cause of your LED flickering. Visible flicker may be considerably decreased by raising the PWM frequency, which is usually set to 500 Hz or 1 kHz. A steady output can be more easily achieved by modifying these values via software on many microcontrollers.

Overheating Concerns

When your circuit gets too warm, it might indicate that the resistor values are off. It is essential to choose a resistor that properly restricts current in order to avoid damaging the microcontroller and the LED. Make sure you’re using the appropriate resistor rating for your particular LED requirements at all times.

Dimming Inconsistencies

If an LED does not dim as expected, the issue may lie in the duty cycle settings within your code. Some LEDs exhibit nonlinear brightness curves, meaning that not all duty cycle values will result in a proportional brightness change. You may need to experiment with your PWM values to achieve the desired smooth dimming effect.

Conclusion

In conclusion, the “Hook Up LED to Pie PWM DAM” system represents a significant stride in the evolution of electronic design, showcasing how simple components can synergistically create complex functionalities. Through the integration of LEDs, piezoelectric sensors, and Pulse Width Modulation (PWM), this setup not only enhances energy efficiency but also fosters an innovative approach to interactive technology. By utilizing the dam analogy, we can better understand the vital role of regulating electrical signals within the system, ensuring optimal performance and safety. The practical applications of this configuration, from smart lighting to interactive installations, highlight its versatility and potential impact across various industries. As we continue to explore and harness these technologies, the future of electronics promises to be marked by creativity, efficiency, and user-centered design.

Read More Information About Technology visit Discover Paradox