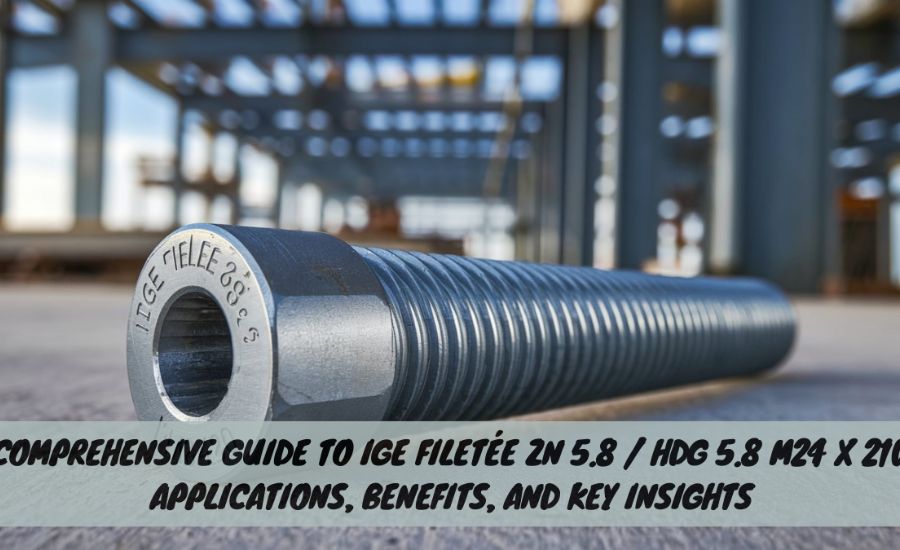

Ige Filetée Zn 5.8 / Hdg 5.8 m24 x 210, Significance Threaded, Process & More

Introduction

Threaded rods are indispensable components in the fields of manufacturing and engineering, playing a vital role in ensuring stability and support across various applications. Among the numerous threaded rod options, the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 stands out due to its exceptional attributes and versatility. This specific model is designed with precision, incorporating robust engineering that meets the demands of both structural and mechanical applications.

What sets the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 apart is its superior tensile strength, which allows it to withstand substantial loads without compromising its integrity. Additionally, this threaded rod is treated for corrosion resistance, making it an ideal choice for use in harsh environments where exposure to moisture and chemicals can compromise structural components. The combination of these features not only enhances its reliability but also extends its service life, thereby reducing maintenance costs for projects.

The relevance of the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 goes beyond mere specifications; it plays a crucial role in the construction and engineering sectors, ensuring that structures remain stable and durable over time. Whether it’s utilized in residential projects or large-scale infrastructure developments, this threaded rod provides essential support that enhances the safety and reliability of various constructions.

In modern engineering, the significance of high-quality materials cannot be overstated. The Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 is not just a product; it is a cornerstone in the construction toolkit, helping to fortify the frameworks of buildings, bridges, and other critical infrastructures. Its design allows for easy integration into various assemblies, streamlining the construction process while ensuring adherence to safety standards.

Overall, the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 exemplifies how advanced engineering materials can elevate project outcomes. By delivering both strength and durability, this threaded rod plays a fundamental role in modern construction practices, highlighting the importance of reliable components in achieving engineering excellence. As industries continue to evolve, the demand for high-performance materials like the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 will only grow, solidifying its position as a critical element in the ongoing quest for innovation and safety in construction.

An overview of the HDG 5.8 M24 x 210 Threaded Rod and Ige Filetée Zn 5.8

The Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a specialized threaded rod widely utilized in construction and engineering. The term “Ige Filetée” refers to a threaded rod in French, while “Zn 5.8” denotes a zinc coating and a strength grade of 5.8. Its dimensions, M24 x 210, indicate a diameter of 24 millimeters and a length of 210 millimeters, making it ideal for applications demanding accurate and dependable structural support.

Constructed primarily from carbon steel, these rods undergo treatments such as zinc coating or hot-dip galvanization. The zinc layer offers corrosion resistance, enhancing durability in moderate conditions, while hot-dip galvanization provides a thicker shield against harsher environments.

In various applications requiring robust support, the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 excels. Its combination of material strength and protective coatings ensures that it performs reliably in both indoor and outdoor settings, contributing to the integrity and safety of structures over time.

The Significance of Accurate Measurements in Threaded Rods

The designation **M24 x 210** provides essential information about the dimensions and compatibility of a threaded rod for various applications. The “M24” signifies a diameter of **24 millimeters**, making it suitable for heavy-duty tasks that require exceptional strength and durability. This robust diameter ensures that the rod can effectively support significant loads. The “210” represents the rod’s length in millimeters, indicating how it can be utilized in different structural or mechanical configurations. This length is crucial for ensuring the rod fits properly in its intended application.

Precision in measurements is vital for the effective functioning and safety of threaded rods.Precise measurements ensure a suitable fit, which is crucial for offering the required steadiness and reinforcement. Deviations from these requirements, even if modest, may lead to faulty installation and subsequent structural failures. Consequently, it is essential to pay close attention to detail both during the production and installation processes.

In conclusion, the **M24 x 210** specification defines the key size parameters that affect the rod’s suitability and performance. Adhering to precise measurements ensures the threaded rod fulfills its role effectively, maintaining the integrity and reliability required in various demanding applications. By following these standards, manufacturers and engineers can mitigate potential issues and guarantee optimal performance.

An Overview of the Manufacturing Process for Threading and Coating

Overview of the Threading Process

The threading process involves creating grooves along the surface of a rod, allowing components like nuts to be securely attached. Usually, a die-cutting system is used to carry out this procedure, guaranteeing precise and uniform thread formation. Manufacturers may ensure that the threaded rod fits precisely and functions well in its intended uses by keeping uniformity throughout the threading process.

Coating Methods Explained

The rod is coated after threading to improve its resilience to environmental stresses and lengthen its lifespan. Zinc electroplating is a popular technique that provides a minimal level of corrosion protection to rods by coating their surface with a thin layer of zinc. By submerging the rod in molten zinc, hot-dip galvanisation, on the other hand, produces a thicker, more resilient protective layer. This procedure greatly extends the rod’s lifespan and improves its overall performance by offering greater resistance against environmental stresses.

Advantages of Threading and Coating

The combination of precise threading and effective coating techniques greatly enhances the quality and functionality of threaded rods. Secure component fastening is ensured by properly shaped threads, and the rod is shielded from corrosion and wear by protective coatings. These methods enable producers to produce threaded rods that satisfy exacting requirements for dependability and durability, qualifying them for a wide range of commercial and industrial uses.

Key Features and Benefits of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a preferred choice in the construction and industrial sectors for several compelling reasons:

1. Excellent Corrosion Resistance

The rod’s zinc coating provides exceptional protection against corrosion, making it particularly suitable for outdoor environments where exposure to moisture and elements can lead to rust. The hot-dip galvanization (HDG) process ensures a thicker, more robust layer of zinc compared to standard zinc plating, enhancing its durability over time.

2. Impressive Strength (5.8 Class)

Rated at 5.8, this threaded rod offers an ideal combination between tensile strength and ductility. It offers a safer alternative in dynamic circumstances where stress is an issue since it can withstand heavy loads with some modest deformation allowed under extreme conditions.

3. Ideal for Heavy-Duty Applications

With a diameter of 24mm (M24), this rod is designed for heavy-duty applications.It excels in various contexts, from steel frameworks and machinery assembly to equipment anchoring, demonstrating its capability to handle significant loads without compromising structural integrity.

4. Precision Engineering

The IGE Filetée rods are crafted with precision threading, ensuring compatibility with nuts and other fastening components. The dimensions M24 x 210 are tailored for structural applications, where achieving exact fits is critical for maintaining stability and safety.

These attributes make the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 a reliable and efficient solution for a wide range of industrial and construction needs.

Common Uses of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is renowned for its versatility and durability across various industries where strength and corrosion resistance are paramount. Here are some typical applications:

1. Construction and Structural Engineering

In steel frame construction, this threaded rod is frequently used and is essential for fastening beams, columns, and other structural components. Because of its strong construction and superior resistance to corrosion, it is especially useful outside, maintaining the integrity and stability of the entire building.

2. Machinery and Equipment Assembly

M24 threaded rod is a necessary item for large part fastening in industries that work with heavy machinery installation or maintenance. Applications where preserving strength and stability is essential include automotive assemblies, agricultural machinery, and industrial gear.

3. Bridges and Heavy Infrastructure

In major infrastructure projects like bridges, this threaded rod is integral to securing the support structure. Because of its great tensile strength and resistance to external influences, it is the perfect material for load-bearing components, guaranteeing durability and security under harsh circumstances.

4. Industrial Fastening Systems

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is widely used in various industrial applications, securing systems such as conveyor belts, assembly lines, and piping networks. Its capacity to endure heavy usage and stress over extended periods makes it an excellent choice for robust industrial environments.

By providing reliable support and exceptional durability, the IGE Filetée threaded rod proves to be an indispensable asset across a wide range of industrial and construction applications.

FAQs Regarding HDG 5.8 M24 x 210 and IGE Filetée Zn 5.8

1. What is the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod?

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a high-quality threaded rod designed for various construction and industrial applications. It features a diameter of 24 millimeters and a length of 210 millimeters, making it suitable for heavy-duty tasks requiring strength and durability.

2. What materials are used to manufacture this threaded rod?

This threaded rod is primarily made from carbon steel and is coated with zinc to enhance corrosion resistance. The hot-dip galvanization process used ensures a thick protective layer, making it ideal for outdoor and harsh environments.

3. What are the benefits of using the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210?

This threaded rod offers several advantages, including excellent corrosion resistance, impressive tensile strength, and precise engineering. It’s suitable for heavy-duty applications and provides reliable support in various construction and industrial settings.

4. In what applications is the IGE Filetée threaded rod commonly used?

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is widely used in steel frame construction, machinery assembly, bridge support, and industrial fastening systems like conveyor belts and piping networks.

5. Why is corrosion resistance important for this threaded rod?

Corrosion resistance is crucial because it extends the lifespan of the threaded rod, especially in outdoor or harsh environments where exposure to moisture and chemicals can lead to rust and deterioration. The zinc coating helps protect the rod and maintain its structural integrity over time.

6. How does the threading process work?

The threading process involves creating grooves along the rod’s surface, allowing nuts and other fastening components to attach securely. This is typically done using a die-cutting system to ensure uniform and precise thread formation.

7. Why is precision in measurements important for threaded rods?

Precision in measurements ensures that the threaded rod fits correctly in its intended application. Accurate dimensions are essential for providing stability and support; even minor deviations can lead to improper installation and potential structural failures.

8. Can the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 be used indoors?

Yes, while it is particularly suitable for outdoor applications due to its corrosion resistance, the IGE Filetée threaded rod can also be effectively used in indoor settings that require strong, reliable fastening solutions.

9. What standards or certifications does the IGE Filetée threaded rod meet?

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 typically meets industry standards for strength and corrosion resistance, ensuring its suitability for various structural and mechanical applications. It’s advisable to check with the manufacturer for specific certifications.

10. How do I determine the right threaded rod for my project?

When selecting a threaded rod, consider factors such as the load requirements, environmental conditions, and compatibility with existing components. The dimensions, material properties, and protective coatings are also essential to ensure optimal performance in your specific application.

Final Words

The Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rod is a vital component in construction and engineering, known for its strength, durability, and corrosion resistance. With a diameter of 24 mm and a length of 210 mm, it is specifically designed for heavy-duty applications, ensuring stability and reliability in various structural and mechanical setups.

What sets this threaded rod apart is its excellent tensile strength and protective zinc coating, which helps it resist rust and wear, especially in outdoor environments. This makes it an ideal choice for construction projects, machinery assembly, bridges, and industrial fastening systems. Its precise threading allows for easy integration with nuts and other fastening components, enhancing its effectiveness.

In summary, the Ige Filetée Zn 5.8 / HDG 5.8 M24 x 210 is not just a piece of hardware; it’s an essential tool that ensures safety and integrity in the structures and systems we rely on every day. By choosing high-quality materials like this threaded rod, engineers and builders can ensure their projects stand the test of time.

Read More Information About Blog At discoverparadox